Advantages of CNG

CNG advantages

- Vechiles running on CNG is more efficent than benzine by %70-80, LPG by %40-50

- CNG doesn’t damage to motor and oil needs to be changed at 35000-40000

- Engines using natural gas is more durable and last longer than other fuels. Natural gas is a clean burning fuel that reduces vehicle maintenance

- Unlike other liquid fuels, there is no risk to be stolen by pulling out. Especially at large fleets, that prevents the risk of fuel theft.

- Being transfering by natural gas pipeline, unlike LPG, diesel and benzine transferring by track, doestn’t cause hazards, environmental pollution and extra cost.

- Ignition temperature of Benzine is 300 °C, LPG is 400 °C and CNG is 650 °C. Because of physical features, ignition of CNG is more diffucult

- According to benzine spoiling on floor and LPG which is heavier than air, natural gas mixes into air quickly in case of an accident.

- Natural gas which is lighter than air, mixes into air, doesn’t accumulate on floor and doesn’t cause explosive and flamable environment unlike other fules (LPG, benzine, etc) in case of accident or leakage. Natural gas has least risk of ignition. It is flammable when mixture of gas/air is between % 5~15

- Lower maintenence cost

- Today, every country that are sensitive to environmental pollution, uses natural gas at their bus, taxi and public transport. Natural gas provides safe, economical and ecological features

- Natural gas produces %90 less nitogen and %25 less carbon monoxide than other fuels.

- Unlike other alternative fuels, natural gas doesn’t involve aldehyde and other air toxins.

- Noise pollution rate is less than 30% compared to engines running on other fuels.

- Level of causing greenhouse effect is very low

- Because of not being toxic and corrosive, natural gas doesn’t pollute water.

- Extends the lifetime of methan.

- Today, natural gas is the most reliable, eco-friendly and economic fuel among all other fuel types. Saving is at the maximum level, comparing with benzine, LPG and diesel, natural gas . In other words, natural gas causes more saving than benzine by %62, LPG and diesel by %40.

CNG / LPG Composite Cylinders (Type IV)

Completely carbon fiber wrapped special plastic inside of cylinder. Natural gas is economic and high energic. Using as an alternative power at internal-combustion engines. Reducing air pollution at minnimum.

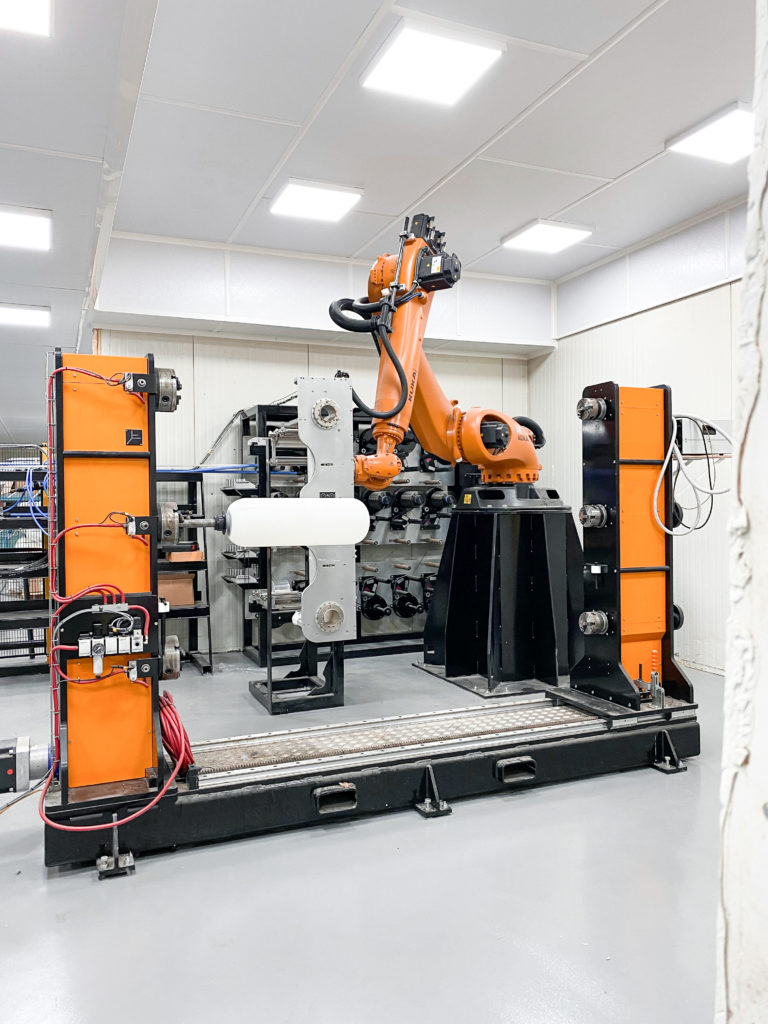

CNG System

CNG is compressed natural gas. Natural gas coming from natural gas pipeline at pressure min 2, max 20 bar and using at houses and industry, is increased to 200 bar pressure by CNG compressor.

Why should we use CNG?

CNG is a type of gas that fires at 650oC and doesn’t have risk to explode. It is an environment friendly gas because the ratio of CO is %0

The unique gas that covers European Emission standart Euro 5 without processing

Difference from other fuels

CNG is %60-%70 more economic than benzine, %30 more economic than LPG.

Our country have an important location in terms of tranferring natural gas. That’s why, in near future, natural gas using at almost every sectors, will provide significant savings at transportation and industry.

How is it used?

CNG is used at the time of vechile manufacturing by mounting special equipment. Modifications at vehiles register according to standarts of vechile mounting directive. Vechiles that use two kinds of fuel can make fuel choice every time. Problems occuring with diesel, benzine and LPG at cold wheathers, don’t occur at CNG.

CNG conversin kits are used safetly in Argentina, Italy, USA, France, Russia, England, India, Pakistan, China, New Zelland and many other countries.

COMPOSITE CYLINDERS (TYPE IV)

- Seamless poymer, welding free

- Internal shell is made of special gas tight PE.

- Special desing boss

- Corrosion free PE liner

- High pressure resistant carbon fiber wrapped outer liner.

- %70 lighter than Type I,II and III.

- Light weight reduces transport and work costs

- Fatigue resistant non metalic liner

- 20 years service life

- Application on wide range vechiles; cars, buses, tracks, forklifts, boats, ships, lokomotives, etc

- Tailor-made productions to meet costumers’ need.

- Production comply with certifications

Completely carbon fiber wrapped special plastic inside of cylinder.

Natural gas is economic and high energic. Using as an alternative power at internal-combustion engines. Reducing air pollution at minnimum.

|

Features of Product |

Advantages |

|

Light weighted |

Wide range of usage |

|

Robustness |

High-pressure resistant because of completely carbon fiber wrapped special plastic inside of cylinder |

|

Corresionprof plastic inside shell |

Special plastic inside shell provides long using life. No corresion during reloading and reunloading provides many years usage. No performance degredations at any environment conditions. Resistant to gas leakage. Flexible plastic inside shell is resistant to cracking and exploding. |

|

High technology carbon fiber material |

Excellent resistant to heat and aging. Leakproof under any circumstances. |

|

Economic and Easy usage |

Used vechiles can be converted easily and cheaply. |

|

Processing suitable for customer. |

Processing according to customers’ needs. Processing high technologic and with best raw material. |

|

MODEL |

DIAMETER |

HEIGHT |

WEIGHT |

WATER VOLUME |

|

Type 4-28 Type 4-80 Type 4-125 |

235 mm 350 mm 350 mm |

735 mm 1065 mm 1610 mm |

11 kg 28 kg 37 kg |

28 lt 80 lt 125 lt. |

Cylinder Categories

|

CNG Type I |

Complete metal cylinder made of carbon or light steal. |

|

CNG Type II |

Steal or aluminium metal covered and filaman top wrapped as a circle inside filaman resin matrix cylinder . |

|

CNG Type III |

Aluminium or metal coverred and filaman top wrapped completelly inside filaman resin matrix cylinder. |

|

CNG Type IV |

Plastic (completelly composite) coverred and top wrapped completelly inside filaman resin matrix cylinder. |

CNG COMPOSITE CYLINDERS (TYPE IV)

Features of CNG Tanks;

|

|

Periodic calibration of loaded CNG cylinders should be done. During loading of natural gas, pressure should reach 216 bar. Safety above international standards is provided. Cylinders are calibrated according to the pressure above 300 bar and designed to resist to 450 bar. Test period of cylinders should be 5 years. Tested cylinders are labeled. Retested and relabeled cylinders can be used for 5 years more.

CNG cylinders are more resistant to serious collesions and heat than LPG cylinders and benzine storage.

Environmental

Global pollution which is one of problems coming from socio-industry, forces people to protect environment in increasing ratio. In 70s and 80s, fuel type was selected mainly according to strategic safety and economic cost. In 90s, environmental factors were at the forefront. The main reason of development of this consciousness is cheaper cost of non-pollution than cleaning.

Alternative fuels to benzine are;

- Liquid Petroleum Gas (LPG)

- Compressed Natural Gas (CNG)

- Liquid Natural Gas (LNG)

- Methanol

- Ethanol

- Hydrogen

This document contains LPG and CNG which are most widely used among alternative fuels.

Light Weight

|

Specific Weight of CNG Cylinders * |

||

|

CNG Tip I |

Complete metal cylinder made of carbon or light steal. |

|

|

CNG Tip II |

Steal or aluminium metal covered and filaman top wrapped as a circle inside filaman resin matrix cylinder. |

|

|

CNG Tip III |

Aluminium or metal coverred and filaman top wrapped completelly inside filaman resin matrix cylinder. |

|

|

CNG Tip IV |

Plastic (completelly composite) coverred and top wrapped completelly inside filaman resin matrix cylinder. |

|

|

* Average Parameter for Standart CNG Pressure Vessels kg/l |

||

Economic

- Reduce maintanence because natural gas is a clean burning gas

- Natural gas used by high compressed bus engines, provides excellent driving performance.

- Unlike other liquid fuels, no risk to be stolen by pulling out.

- Cylinders can be loaded in 3-4 minutes at stations which are fast and have big compressors

- At a system working with natural gas, ratio of greenhouse effect and toxic material are much lower than a fuel oil or an alternative engine.

- As a feature of natural gas system, evaportion emission is close to zero. This means, at least %50 of total hydrocarbon is evaluated.

- As a feature of natural gas, emission ratio of CO2 reduces over %20.

- According to reseachs in many cities of USA, diesel exhausts are responsible for creation of some kinds of tiny particules increasing risk of respiratory tract diseases. However, just a few of these particules are found at natural gas systems.

- It is certain that expansion of using natural gas in a country or a region of a country, creates new job areas.

Safe

Inside of CNG Type IV cylinder is made of plastic, so it doesn’t do bomb effect in case of an explosion.Plastic inside shell just bursts and the gas just flies away in a few seconds, because CNG is lighter than air.

Other CNG cylinders (Type 1-2-3) themselves or insides are metal, so they do bomb effect in case of an explosion, spreads away like shrapnel. This causes life and goods loss.

There are two important structure as safety factors at natural gas systems.

- Special design of natural gas systems

- Physical and chemical features of natural gas

Using industry and home natural gas is safer than diesel and coal. Because unlike liquid and solid fuels, natural gas is mixed into atmosphere in case of leaking. However liquid fuels have a huge risk of spoiling on ceiling and causing to fire.

Natural gas cylinders are more resistant to physical and chemical effects than other fuel storages of systems because of composite materials.

Ratio of evaporation is close to zero, so there is no risk of leakage. Even in case of puncturing of cylinder, natural gas which is lighter gas than air, mixes into air directly without causing any hazzard.

Natural gas whose ignition heat is 6500C, is safer than benzine whose ignition heat is 3500C. Besides, there is no risk of explosion of natural gas unless ratio of mixage with air is between %5 and %15. Natural gas is the most reliable gas in terms of safety according to other liquid fuels in case of an accident because of its high iginiton heat and low range of burning.

Frequently Asked

Questions about CNG

-

Show answer to the question Type IV tanks safe?

Type IV tanks safe?

Inside of CNG Type IV cylinder is made of plastic, so it doesn’t do bomb effect in case of an explosion.Plastic inside shell just bursts and the gas just flies away in a few seconds, because CNG is lighter than air.

Other CNG cylinders (Type 1-2-3) themselves or insides are metal, so they do bomb effect in case of an explosion, spreads away like shrapnel. This causes life and goods loss.

There are two important structure as safety factors at natural gas systems.

- Special design of natural gas systems

- Physical and chemical features of natural gas

Using industry and home natural gas is safer than diesel and coal. Because unlike liquid and solid fuels, natural gas is mixed into atmosphere in case of leaking. However liquid fuels have a huge risk of spoiling on ceiling and causing to fire.

Natural gas cylinders are more resistant to physical and chemical effects than other fuel storages of systems because of composite materials.

Ratio of evaporation is close to zero, so there is no risk of leakage. Even in case of puncturing of cylinder, natural gas which is lighter gas than air, mixes into air directly without causing any hazzard.

Natural gas whose ignition heat is 6500C, is safer than benzine whose ignition heat is 3500C. Besides, there is no risk of explosion of natural gas unless ratio of mixage with air is between %5 and %15. Natural gas is the most reliable gas in terms of safety according to other liquid fuels in case of an accident because of its high iginiton heat and low range of burning.

-

Show answer to the question CNG an Alternative Fuel?

CNG an Alternative Fuel?

In recent years, CNG is accepted as main fuel, but also it is used as an alternative fuel at passenger vechiles. There are many models of vechiles using CNG. Heavy vechiles like buses and tracks are prefered CNG as main fuel. In recent years, CNG engines reached at high technlogy level.

Reducing reserves of petrol and increasing price make alternative fuels as main fuel. CNG and hydrogen become first choice as the result of petrol’s price and effect to the environment. Besides CNG, Hydrogen or HCNG(%20 Hydrogen %80 CNG) can be filled by adding equipment at CNG stations.

After natural gas come out from well with basic cleaning process, transfered through pipeline without effects of air conditions. Filling without storing at CNG stations eases natural gas to spread and establishment of sytem At the same time, simplicity of processing and transport of natural gas causes lower cost than petrol.

Comparing CNG with Other Fuels

Advantages of CNG by other fuels:- Safety standarts of CNG are higher

- CNG is more environmental fuel with low emissions.

- Higher emission than EURO 5 standarts

- CO2 emission is %25 lower at CNG

- Security of supply of natural gas in Turkey is high,

- CNG is heaper than other fuels

- Octane number is 124 and higher.

- Emission of particles is close to zero,

- Being gas state at engines, CNG provies most effective ignition at engines.

- CNG is the fuel causing least knock at engines,

- CNG engines are silent and vibration-free

- The same performance at cold or hot air conditions.

Service buses in ABD, Califonia use CNG necessarily. Usage of CNG at canal boat has been completed in Holand. In many countries, only vechiles running on CNG are allowed to enter in center of the city. These examples proofs superority of the safety and emissions of CNG

Periodic maintenence time extends, Wearing out caused by vibration reduces, CNG doesn’t include contaminants, so oil life extends. Addition of these positive values and very important advantage of its cost makes CNG more economic than other fuels.

Other fuels equals to 1m³ CNG:

1 m³ CNG

1 m³ CNG

1 m³ CNG

1 m³ Benzin

Conversition is according to ABD GGE system. The amount of savings can be calculated according to a bus driving in a city.

Using area of CNG

CNG can be used in two field areas as a compressing of natural gas:- CNG AUTOGAS can be used at vechiles,

- CNG ENERGY in special ransporting container can be transferred to consumers who use it as natural gas and it cen be consumes by reducing pressure.

Vechiles using CNG Autogas

- Automobiles

- Local and non-city buses

- Local logistic vechiles and vechile fleets

- Vechiles like garbage traks and road cleaner

- Heavy vechiles, military and public service vechiles

- Boats using in canals and seas, ferryboat, sea taxis

- Trains, motorcycles, tripators

- Airplains and all kinds of apron tools

- Work machines, earth-moving truck fleets, forklifts

How does CNG use in vechiles?

Basic equipments at CNG vechiles- Suitable engine for CNG

- CNG cylinders

- Fuel line and regulators

CNG cylinders and Technology

Cylinders that is suitable for being filled CNG are seperated as made of steal and other chemicals. Comparasion between steal and carbon fiber cylinders is below.Carbon fiber

Steel

Water Capacity

I

102

100

Tare Weight

kg

38

103

Full Weight

kg

56.3

42.8

CNG Capacity

m3

25.8

25

Pressure

bar

200

200

Which part of vechiles can be filled with CNG?

CNG is filled with equipments that compress natural gas at high pressure and fill in cylinders. Natural gas with different pressures coming to pipeline, is increased to He 200 or 250 bar pressure by compression system. CNG is filled to vechiles by dispensers. According to filling velocity and dispensers capacity, for example 300 m³ in 4 minutes, CNG is filled in a bus tank.Transport System of CNG Energy

The most economic way to transport CNG to consumers where natural gas pipelines can not be reached to, is CNG method. Pressure of Natural gas is increased to 200-250 bar by CNG compressor and gas is loaded at special transport vechiles. Widely used CNG energy transporting cantainers are;:- CNG Battery: 150 m³ at 200 bar,

- CNG cylinders trailer: 4500- 5500 m³ CNG is filled to this vechile consisted of steal cylinders and moved by tow track.

- CNG Cylinder truck: 14,000 m³ CNG is filled to these trailers consisted of 250 bar carbon fiber cylinders and moved by tow truck.

Different sizes of models of hese ttransporting systems can be made. 200 or 250 bar pressure can be chosen. Different stocking technics can be used at consumer area.

Interested in CNG ?

Let’s talk.